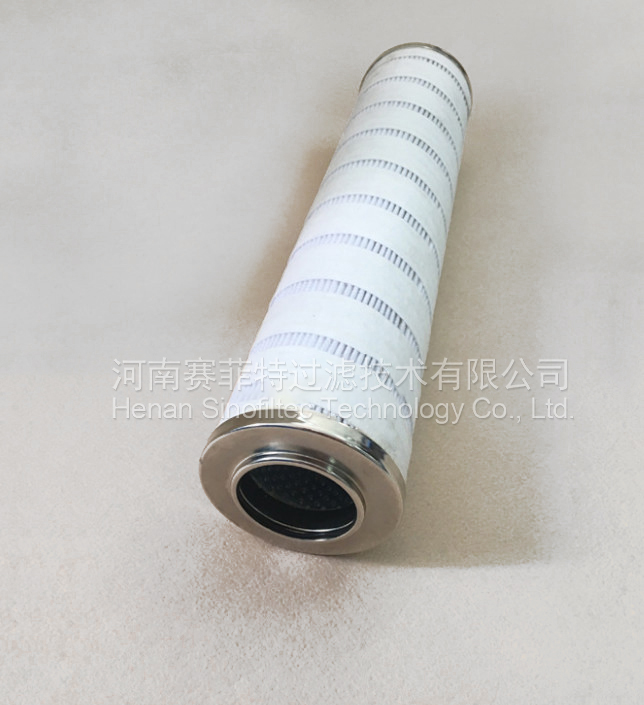

FST-RP-HC8900FKN16H Hydraulic Oil Filter Element

Basic Info

Model No.: FST-RP-HC8900FKN16H Hydraulic Oil Filter Element

Product Description

FST-RP-HC8900FKN16H Oil Filter Element:

Production descible:

The HC8900FKN16H filter element is installed in the middle and high pressure pipeline to protect the upstream of the components, effectively control the contamination of the working medium, and make the hydraulic components work properly. High filtration area provides a long service life of the o-ring inside the hydraulic filter element to effectively prevent contaminants from passing through.

Characteristics and advantages:

HC8900FKN16H series filter elements can be used in different media environment, stainless steel mesh, sintered felt filter, etc. The filtering accuracy can be selected from 1,3 ,6 ,12,25 mircons and so on. Upstream of the protective element to be installed in a medium pressure pipeline.

The use of spiral band to strengthen the support to ensure the stability of the filter material, filter layer with deep filter paper, high capacity of pollution, can make the life of the filter element longer, the inner support skeleton thickened hole plate, improve the overall crushing strength of the filter core. At the joint of corrugated filter material, v-shaped bonding process is adopted, the inherent strength of the material and the strong structural support on both sides of the filter element are adopted. The pressure difference is allowed to fluctuate in a wide range With reasonable combination, the filtration effect is better, high pressure collapsibility and high circulation. The filter element of HC8900FKN16H series instead of PALL is exactly the same size, which can completely replace the original product and achieve the filtering effect of the original factory.

Main advantages:

(1) A new filter material is made for the filter element. The multi-layer filtration structure ensures the ability of separation of high contamination and dirty pollution, uniform texture, corrosion resistance and fatigue resistance.

(2) innovating longitudinal joint technology and perfectly joining the end of filter material, especially under different loads, the effective value can prevent suspended particles from entering the filter zone from the dirt area.

(3) in the operation of filter element, the static electricity can be derived below the safe value, and the continuous formation of black carbon or the formation of silt oil can be excluded.

(4) the original imported filter media has uniform aperture, low resistance and large dust capacity.

(5) Germany imported composite filter folding machine to increase the effective filter area.

(6) oil and temperature resistant cyclopropyl resin adhesive. The seal is firm.

(7) thickened steel plate skeleton. Strong pressure drop resistance.

(8) to leave the factory after passing the inspection. The quality is reliable.

Technical Data:

| Filter element type | High efficiency folding filter |

| Filter medium | Resin consolidated glass fiber high efficiency filter material mixed with wire mesh |

| Accuracy of glass fiber | 1,3, 5, 5, 7, 10, 12, 22 microns available |

| Internal support and end cover material | Metallized tin / reinforced nylon / stainless steel |

| Working temperature | -30℃~120℃ |

| Working pressure | 21Bar~210Bar |

Applications:

1.Metallurgy: used for filtration of rolling mill, continuous casting machine hydraulic system and various lubricating equipment.

2. Petrochemical: separation and recovery of products and intermediate products in refining and chemical production, filtration of oil well water and natural gas.

3.Thermal power and nuclear power: gas turbine, boiler lubrication system, speed control system, bypass control system oil purification, feed Water Pump, fan and dust removal system purification.

4.All kinds of lifting, handling operations: lifting, loading and other engineering machinery to fire, maintenance, handling and other special vehicles, ship crane, anchor, blast furnace, steelmaking equipment, lock, ship door hoist, Theater's lift and lift stage, all kinds of automatic transmission line and so on.

FST-RP-HC8900FKN16H filter element instead of PALL hydraulic oil filter element execution standard:

ISO2491 filter-rupture resistance experiment:

The test of resistance to rupture of filter element belongs to the strength test of the filter element itself. The filter element is generally subjected to external force by the pressure difference limit after carrying the dirt in the filter shell. The inner skeleton is the main support of the filter layer under the limit pressure difference of the filter element, and the collapse of the skeleton will lead to the collapse of the filter layer.

ISO2492 filter element structural integrity experiment:

The significance of the requirement of the integrity of the filter element structure, the filter material is very good, the filter material is broken or made incomplete in the process of making the filter element, the incomplete phenomenon mainly manifests in: the filter material is damaged, the end cover is not glued strictly, the filter material butt joint is not strict and solid. It will greatly affect the original filtering accuracy.

ISO2493 filter element the compatibility betwee material and liquid experiment:

The compatibility test between filter element and working fluid is mainly a validation test of the properties of raw materials used in the process of making filter elements, such as compatibility with petroleum, water diol, water-oil emulsion and liquid with high water content. PTFE seals are standard configurations and can be used in conjunction with industrial phosphate, diesters and specific synthetic materials.

ISO3726 filter element experimental method of the end load:

The end load test of the filter element mainly tests the ability of bearing the axial mounting force, the strength, the axial load, the flattening strength and so on.

ISO3724 filter element the determination of fatigue characteristics:

The test of the fatigue characteristics of the filter element is the test of the life of the filter element. The filter element works in the hydraulic system, withstanding the reciprocating and alternating fluid flow of the system and the pressure impact of the working flow. Under this impact, if the filter element has accumulated pollutants and established a greater pressure difference, then the pressure of the filter layer withstanding the fluid flow will be greater.

ISO3968 filter element determination of flow characteristics and the pressure difference:

The pressure drop flow characteristic is usually an assessment of the filter, but in fact, it mainly evaluates the flow rate and resistance of the filter core. Of course, in the design of filter assembly, there are flow and

bypass problems in the channel design of the shell. But after all, it is not the main problem, the main problem is the filter, so the standard mainly checks the filter, not the filter.

The replacement of PALL company hydraulic filter type Series (FST- RP-xxxxxxxx):

| HC8900FKN39H | HC8900FKN26H | HC8900FKN16H | HC8900FKN08Z |

| HC8900FUZ39H | HC8900FUZ26H | HC8900FUZ16H | HC8900FUZ08H |

| HC8900FUZ39Z | HC8900FUZ26Z | HC8900FUZ16Z | HC8900FUZ08Z |

| HC8900FUT39H | HC8900FUT26H | HC8900FUT16H | HC8900FUT08H |

| HC8900FUT39H | HC8900FUT26H | HC8900FUT16H | HC8900FUT08Z |

Product Categories : Brand Filters Exchanged Series > PALL Filters